When your slack adjuster won’t back off, it can be a major headache. But don’t worry, we’ve got you covered. In this comprehensive guide, we’ll delve into the causes of slack adjuster failure, provide step-by-step troubleshooting tips, and offer expert advice on repair and replacement procedures.

Whether you’re a seasoned mechanic or a DIY enthusiast, this guide will empower you to diagnose and resolve slack adjuster issues like a pro.

Causes of Slack Adjuster Failure

Slack adjusters play a crucial role in maintaining proper brake operation. However, they can fail to back off due to various reasons, compromising brake performance and safety.

Worn Components

Over time, the components within the slack adjuster can wear out, affecting its ability to function correctly. Worn pawls, springs, or ratchets can hinder the adjuster’s ability to back off, leading to excessive brake drag.

Seized Mechanisms

Slack adjusters can become seized due to corrosion, debris accumulation, or improper lubrication. When mechanisms become seized, they can prevent the adjuster from moving freely, causing the brakes to stay engaged.

Improper Installation

Incorrect installation of the slack adjuster can also contribute to failure. Improper adjustment, loose mounting, or misalignment can interfere with the adjuster’s operation, preventing it from backing off effectively.

Examples of Slack Adjuster Failure

- A worn pawl may fail to engage the ratchet, preventing the adjuster from backing off and causing the brakes to drag.

- Corrosion on the adjuster’s mechanism can seize it, keeping the brakes applied even when the brake pedal is released.

- Incorrectly adjusted slack adjusters may not provide enough clearance for the brake shoes to retract, resulting in constant brake engagement.

Troubleshooting Slack Adjuster Issues: Slack Adjuster Won’t Back Off

If your slack adjuster is not backing off, it can be frustrating and dangerous. Here are some steps you can take to troubleshoot the problem and get your brakes working properly again.

First, check the slack adjuster itself. Make sure that it is not seized or damaged. If it is, you will need to replace it. Next, check the brake shoes and drums. Make sure that they are not worn or damaged.

If they are, you will need to replace them.

Inspecting and Testing the Slack Adjuster

To inspect the slack adjuster, you will need to remove it from the brake assembly. Once you have removed it, you can inspect it for any signs of damage. If you see any cracks or other damage, you will need to replace the slack adjuster.

You can also test the slack adjuster to make sure that it is working properly. To do this, you will need to apply pressure to the brake pedal. If the slack adjuster is working properly, the brake shoes will move away from the brake drums.

If the slack adjuster is not working properly, the brake shoes will not move away from the brake drums.

Repair and Replacement Procedures

If the slack adjuster fails to back off, it may need to be repaired or replaced. The repair or replacement procedure involves removing the old slack adjuster, inspecting it for damage, and replacing it with a new or repaired unit.

If you’re struggling with a slack adjuster that won’t back off, you’re not alone. Many people have experienced this frustrating issue. If you need a break from troubleshooting, you can check out the Desiree’s Baby PDF Answer Key to catch up on some reading.

Once you’re refreshed, you can come back to your slack adjuster problem with a fresh perspective.

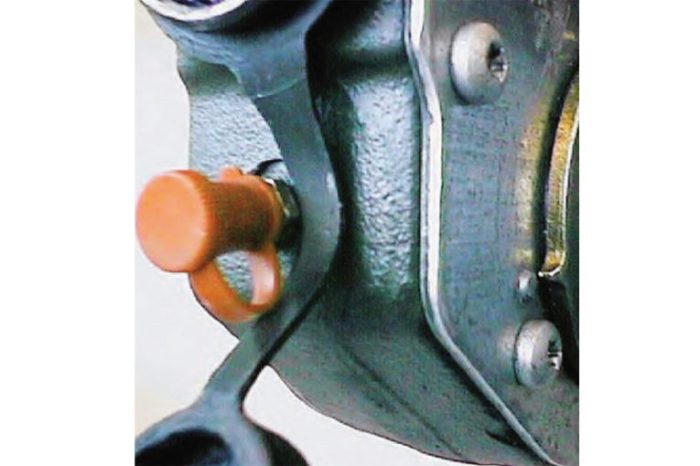

Slack Adjuster Removal

- Disconnect the battery.

- Locate the slack adjuster on the brake assembly.

- Remove the cotter pin or bolt that secures the slack adjuster.

- Pull the slack adjuster off the brake shoes.

Slack Adjuster Disassembly

- Remove the spring clip that holds the adjuster arm in place.

- Remove the adjuster arm.

- Remove the adjuster screw.

- Inspect the adjuster screw and adjuster arm for damage.

Slack Adjuster Installation

- Install a new or repaired adjuster screw into the adjuster body.

- Install the adjuster arm onto the adjuster screw.

- Install the spring clip that holds the adjuster arm in place.

- Install the slack adjuster onto the brake shoes.

- Install the cotter pin or bolt that secures the slack adjuster.

- Connect the battery.

Slack Adjuster Adjustment

- Pump the brake pedal several times to adjust the slack adjuster.

- Check the brake pedal travel.

- If the brake pedal travel is too long, tighten the adjuster nut.

- If the brake pedal travel is too short, loosen the adjuster nut.

Maintenance and Prevention

Regular maintenance and inspection are crucial for preventing slack adjuster failure and ensuring optimal performance. Proper lubrication and adjustment extend the lifespan of the slack adjuster and related components, minimizing the risk of costly repairs and downtime.

Importance of Regular Maintenance and Inspection, Slack adjuster won’t back off

Regular maintenance and inspection help identify potential issues early on, allowing for timely repairs or adjustments before they escalate into more severe problems. This proactive approach prevents premature wear, corrosion, and other issues that can compromise the slack adjuster’s functionality.

Proper Lubrication

Lubricating the slack adjuster’s moving parts is essential for smooth operation and reducing friction. Use a high-quality lubricant specifically designed for automotive brake systems. Apply lubricant to all moving surfaces, including the pivot points, threads, and linkages. Proper lubrication minimizes wear, prevents corrosion, and ensures smooth adjustment.

Proper Adjustment

Regularly check and adjust the slack adjuster to maintain the correct brake shoe clearance. Incorrect adjustment can lead to premature brake wear, reduced braking performance, and increased stopping distances. Follow the manufacturer’s recommended adjustment procedures and use a slack adjuster tool to ensure accurate adjustment.

Tips and Recommendations

- Monitor brake performance and listen for any unusual noises during braking, as these could indicate a problem with the slack adjuster.

- Avoid using excessive force when adjusting the slack adjuster, as this can damage the adjuster or other brake components.

- Inspect the slack adjuster for any signs of damage, corrosion, or wear during regular maintenance. Replace any damaged or worn components promptly.

- Clean the slack adjuster and surrounding areas regularly to remove dirt, debris, and brake dust that can interfere with its operation.

User Queries

Why won’t my slack adjuster back off?

Slack adjusters can fail to back off due to worn components, seized mechanisms, or improper installation.

How do I troubleshoot a slack adjuster that won’t back off?

Start by inspecting the slack adjuster for any visible damage or wear. Then, check the brake shoes and drums for any signs of excessive wear or contamination.

How do I repair or replace a slack adjuster?

Repairing or replacing a slack adjuster requires removing the brake drum, disassembling the slack adjuster, and installing a new or repaired unit. Follow the manufacturer’s instructions carefully for proper installation and adjustment.